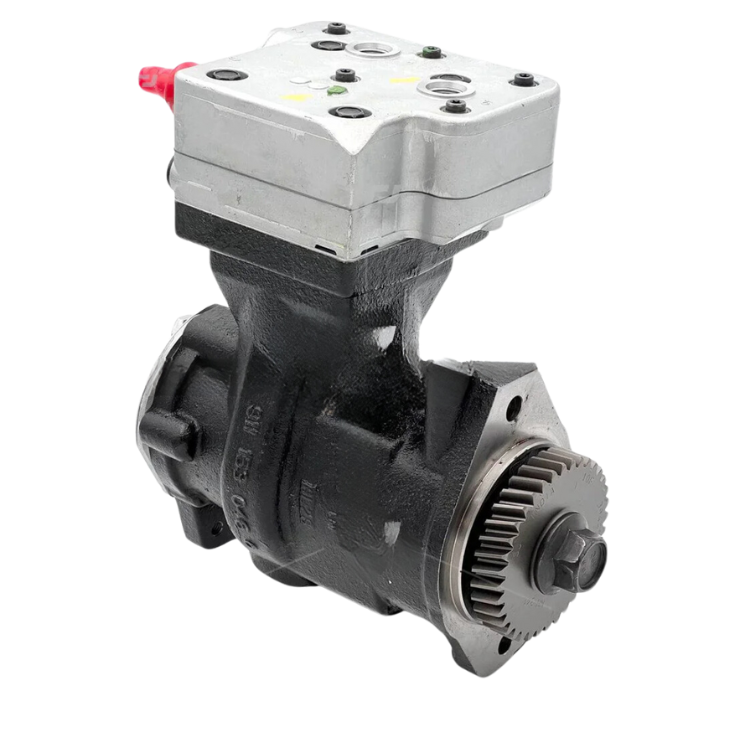

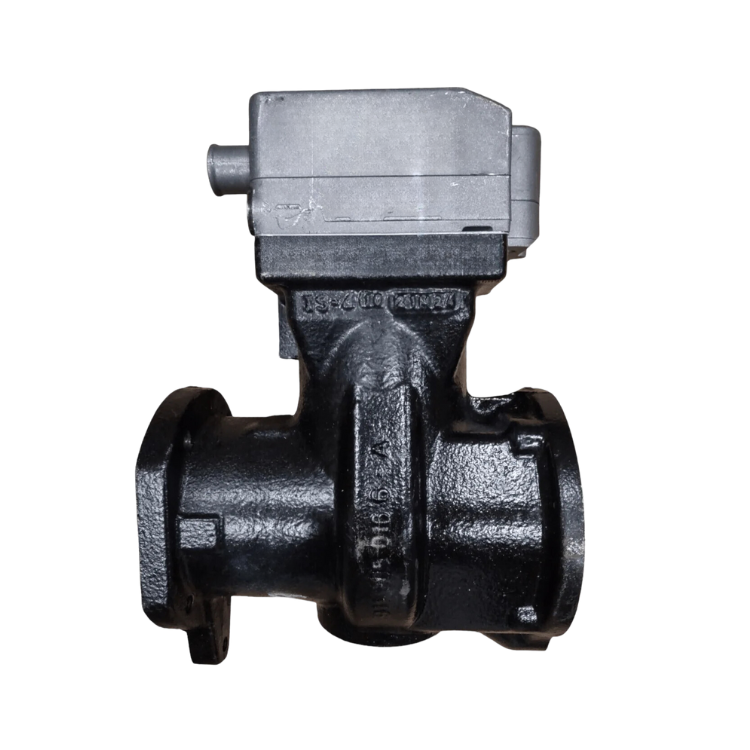

Cummins ISM, N14, M11 Air Brake Compressor 1996-2004: OEM 3417958RX

CUMMINS ISM, N14, M11 AIR BRAKE COMPRESSOR 1996-2004: OEM 3417958RX

ORDERS PLACED BEFORE 3PM EST WILL SHIP SAME DAY

WARRANTY

1M MILES OR 1 YEAR

PRODUCT DESCRIPTION

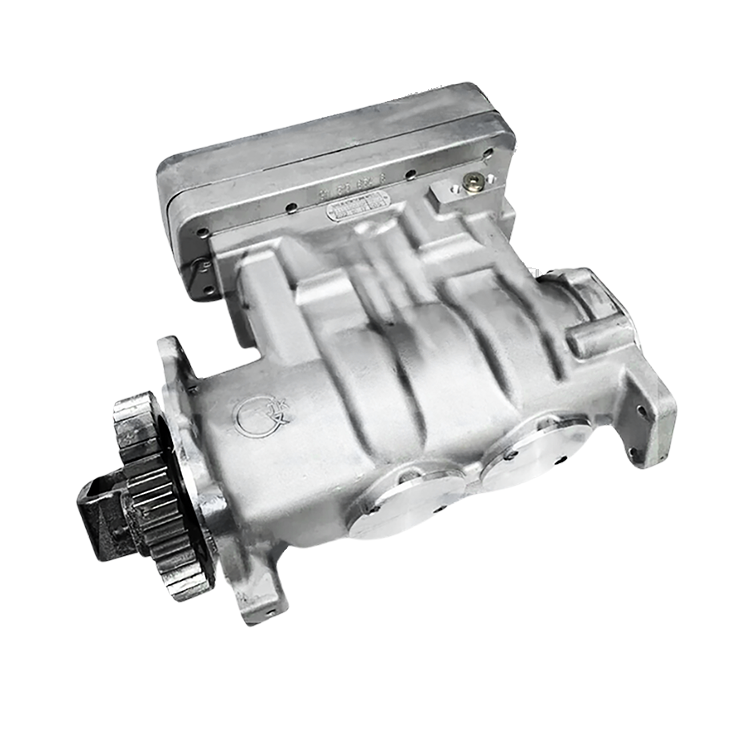

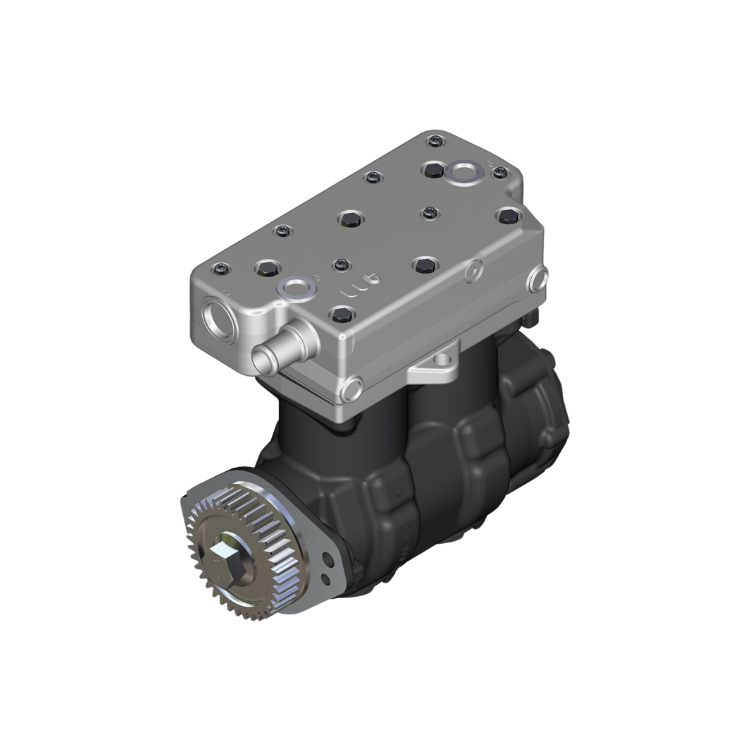

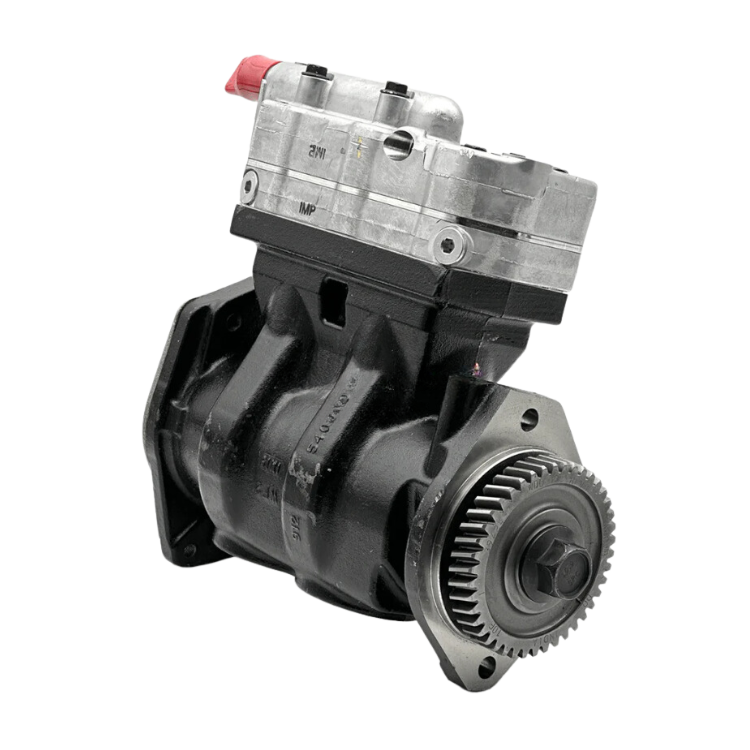

This is a Remanufactured Tamerx Air Brake Compressor, Tamerx part number 3417958RM ( OEM Part Number 3417958RX ). All parts are proudly remanufactured in the U.S.A. to the highest of OEM standards, and improvements are often applied to the original design in the remanufacturing process. This part is primarily made for a Cummins ISM, N14, M11, production years 1996-2004, and comes with a One Million Miles or One Year Warranty. For additional warranty info Click Here

OEM NUMBERS

| Primary OEM | 3417958RX |

| Additional OEM | 107506X, 3074470, 3417958RX |

ADDITIONAL DETAILS

| CONDITION | Remanufactured |

| UPC / Barcode | |

| WEIGHT | 58.00 LBS |

SHIPPING OPTIONS

Ship Weight : 58.00 LBS

UPS Ground, 2nd Day Air, Next Day Air

SHIPPING POLICY

Tamerx Diesel Products ships via UPS Ground. Next day air shipping can be arranged for a reasonable price of anywhere from $50.00 - $100.00 depending on the weight of the product and your location. We will do everything we can to make sure that you get the service you need. We understand how important it is to receive your order as quickly as possible.

In most cases Tamerx Diesel Products only needs one address, as long as your product is shipping to the same location as your billing information. In order to eliminate credit card fraud, your billing information must match the credit card you provide.

The terms, conditions, and details of our warranty vary from product to product. Specific warranty details can be found below.

Tamerx Diesel Products provides a replacement warranty on all of our parts. The duration and mileage limitations of the warranty vary by product and are specified on the product's detail page/item listing.

Please note that the warranty covers replacement of the part and the cost of shipping the replacement part to you only. It does not cover any shop, labor, towing, or any similar or related costs. This is not a "money back guarantee".

If you experience a problem with your part or it is not functioning properly, the correct warranty procedure is to call us at (510) 257-1777 (8:00 AM - 5:00 PM ET Monday through Friday). Be sure to have your order number and/or other relevant order information ready so we can easily locate your order and resolve your issue as quickly as possible. From that point, we will review with you any troubleshooting steps that may need to be taken and other areas or systems that can be checked to rule out external problems contributing to your part's issue. If a replacement is determined to be necessary, we will then arrange for your replacement part to ship out ASAP and issue any necessary return shipping labels and/or documents.

As is the case for the majority of the diesel products sold on Tamerx Diesel Products, your part's warranty is active as soon as you install it. In some other cases, warranty activation is contingent upon you sending us your core (i.e., your old part). Tamerx Diesel Products will provide you a return shipping label for parts that have a warranty with a core return condition. When we have received your core return, the part's warranty coverage begins. We reserve the right to void the product warranty if your core is not received within the allotted time, or if it isn't received at all. If the warranty for the diesel part you are purchasing has a core return requirement, it will be clearly noted on the product detail page/item listing.

What is a Core Charge?

A core charge (also called "core deposit") is similar to the deposit you might pay for a can or bottle of soda and is a standard requirement in the auto parts industry. For example, in many states, to promote recycling, you pay a deposit when you purchase a can of soda and receive your deposit back when you return the empty can. Many automotive parts have a core charge, or core price, that works in essentially the same way as a soda can deposit.

30 Day Core Charge Hold

You authorize Tamerx Diesel Products, to hold your credit card for the specified core charge amount and that you agree to return your core with 30 days of receiving the purchased part. When we have received your core return, the hold is released and the core charge payment is canceled.

The customer, or parts buyer, is responsible for any shipping costs associated with core returns unless otherwise specified in the product listing/detail page. Tamerx Diesel Products offers prepaid UPS shipping labels (SKU numbers UPS-CR1 and UPS-CR2) for use in returning your core that are available for purchase on our website during your shopping/order process.

The shipping label you will need to use for the core return is dependent upon what part you are purchasing. UPS-CR1 is good for cores weighing up to 20 pounds. UPS-CR2 is appropriate for shipping cores weighing 21 pounds or more. You must include enough information with the core return that clearly identifies it as a.) a Core Return, and b.) contains enough information we can use to clearly associate the core return with your order. Including a copy of the invoice or packing slip that came with the original shipment, clearly marked "Core Return", is ideal. Alternately, you can include a note marked as "Core Return" that includes your order number, full name and address, and phone number or other contact information. Failure to include this information with your returned core will most likely delay any due core credit being issued and/or delay any applicable warranty activation. Core returns need to be for the exact part purchased and cannot be damaged. Substituting another part in place of the part you have purchased is not acceptable.

All fluids must be drained.

If you have purchased a set or a parts package, you will need to return cores for all components of the set. For example, if you have purchaed a high pressure oil pump with an IPR valve, you will need to return both HPOP and IPR valve cores to receive proper credit. If you have purchased an EGR cooler/EGR valve package, your core return must consist of an EGR cooler core and an EGR valve core, or core credit will not be given.

Core Charges are often mandated by state legislature, and, as such, the actual core charge and taxes on the charge may vary depending on the state in which you buy your part. The Tamerx Diesel Products core charge presented to you online today with your item is representative of the most common core charge.

Support dependable braking power with this Air Brake Compressor for Cummins ISM, N14, and M11 engines, OEM 3417958RX, designed for 1996–2004 models. Engineered to supply consistent air pressure to your vehicle’s brake system, this compressor plays a critical role in maintaining safety and performance under heavy-duty conditions. Built to exact OEM specifications, it ensures a direct fit, smooth operation, and long-term durability. Trust Tamerx for reliable air system components that keep your rig road-ready.

FITMENT CHART

| YEAR | MAKE | ENGINE(S) | ||||

|---|---|---|---|---|---|---|

| 1996 | Cummins | ISM | N14 | M11 | ||

| 1997 | Cummins | ISM | N14 | M11 | ||

| 1998 | Cummins | ISM | N14 | M11 | ||

| 1999 | Cummins | ISM | N14 | M11 | ||

| 2000 | Cummins | ISM | N14 | M11 | ||

| 2001 | Cummins | ISM | N14 | M11 | ||

| 2002 | Cummins | ISM | N14 | M11 | ||

| 2003 | Cummins | ISM | N14 | M11 | ||

| 2004 | Cummins | ISM | N14 | M11 | ||

PEOPLE ALSO ASKS | BLOG(S)

Yes, internal seal wear or valve damage can lead to air leaks and pressure loss.

It should be visually checked during routine maintenance and tested during scheduled service intervals.

Yes, it is typically lubricated through the engine’s oil system and relies on clean oil to operate effectively.

Contaminated oil, overheating, or excessive duty cycles can contribute to internal wear and failure.